Table of Contents

Introduction

Welcome to the exciting world of 3D printing, where innovation knows no bounds. In this journey, we delve deep into the heart of the matter — the quest for the strongest 3D printing material. Buckle up as we explore the intricacies, breakthroughs, and challenges in this dynamic field.

Understanding 3D Printing Materials

Before we plunge into the specifics, let’s grasp the fundamentals of 3D printing materials. The evolution of this technology has been a game-changer, revolutionizing industries and giving rise to a demand for materials that can withstand the toughest tests.

The Evolution of 3D Printing

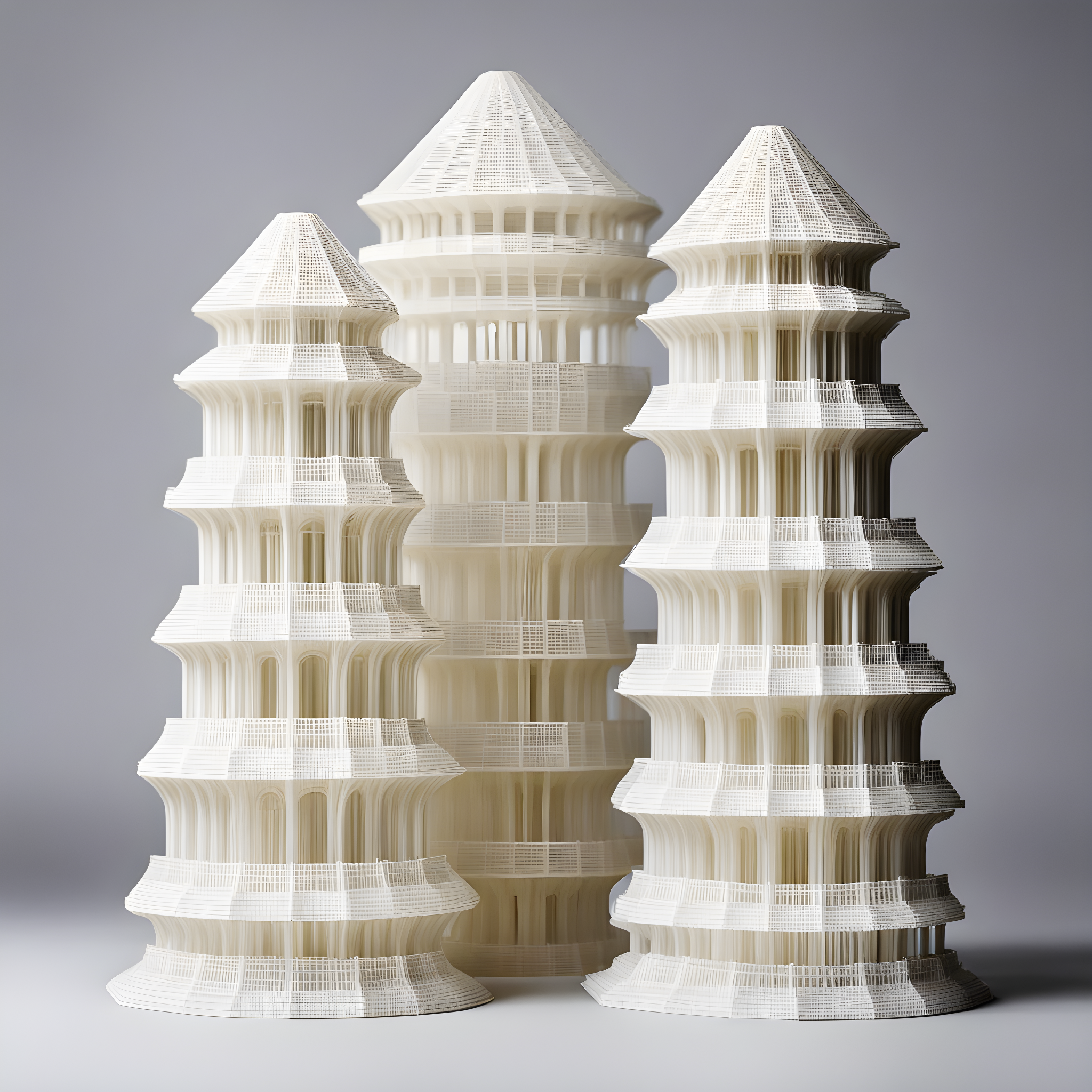

As 3D printing has evolved, so have the materials used. We’ve moved from basic polymers to advanced composites, metal alloys, and cutting-edge ceramics. This evolution has been instrumental in pushing the boundaries of what’s possible.

Key Factors for the Strongest 3D Printing Material

What makes a 3D printing material strong? Several factors come into play, including composition, processing techniques, and the intended application. Let’s unravel the key components that contribute to strength in the 3D printing realm.

Materials in Focus

Metal Composites

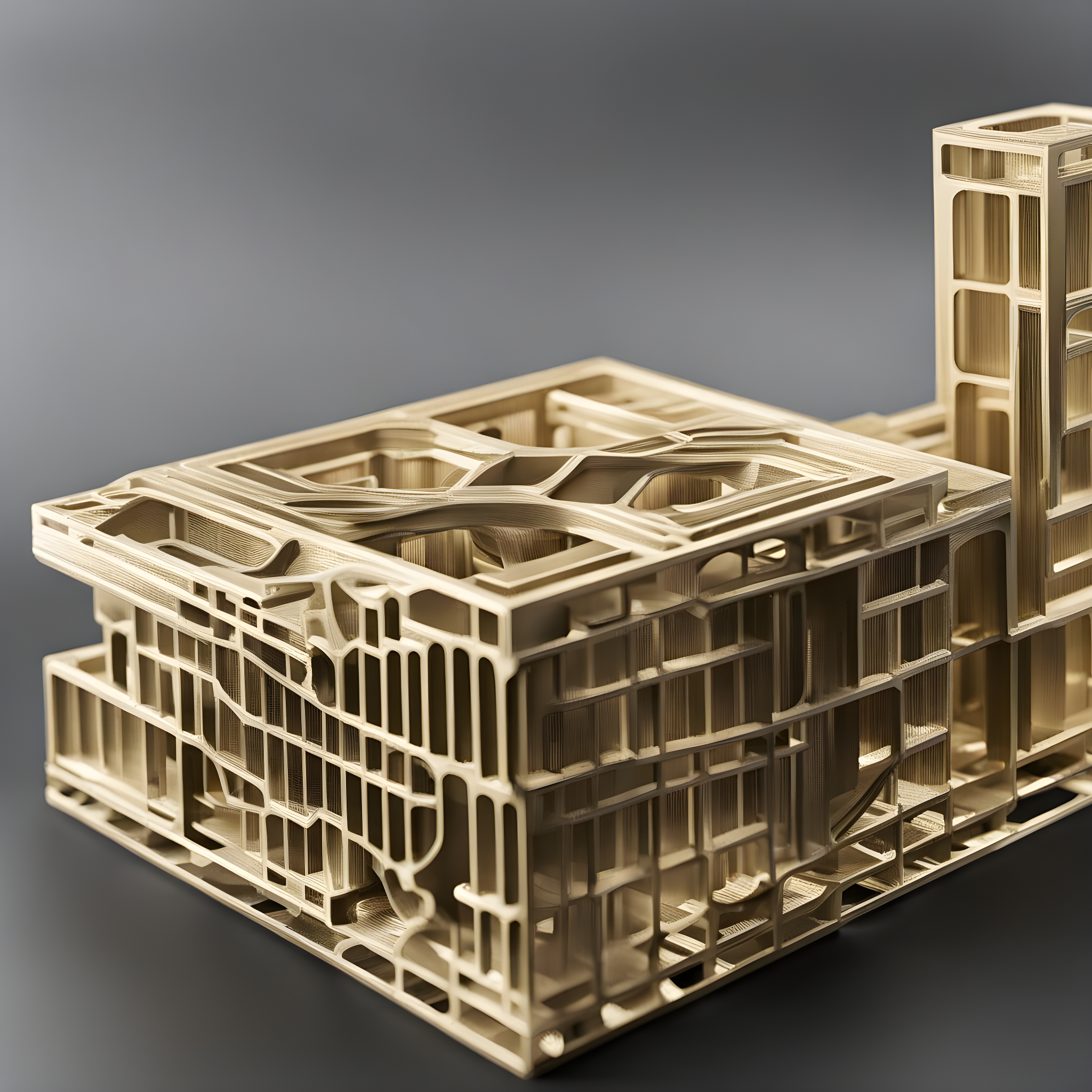

Metal composites have emerged as frontrunners in the quest for strength. The amalgamation of metals with other elements creates materials that boast exceptional tensile strength and durability.

Polymer Blends

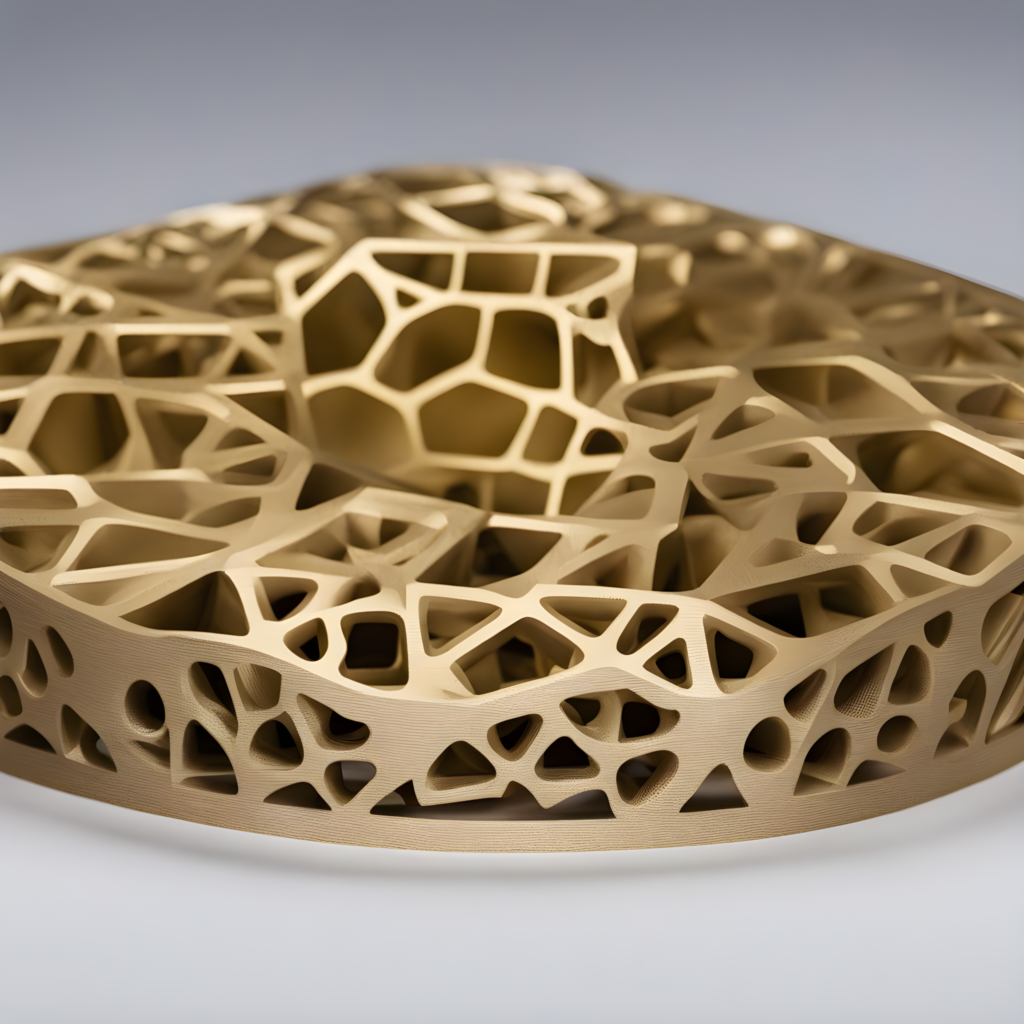

Polymer blends, although lighter, have made significant strides in enhancing their strength. Advancements in molecular structures have led to polymers that rival traditional materials in toughness.

Advanced Ceramics

The utilization of advanced ceramics introduces materials with unparalleled hardness and resilience. These ceramics find applications in critical industries where strength is non-negotiable.

Pros and Cons of Each Material

Each material has its strengths and weaknesses. Metal composites offer robustness but may be heavier, while polymer blends provide flexibility at the cost of some durability. Understanding these trade-offs is crucial in selecting the right material for a given application.

Real-world Applications

The rubber meets the road in real-world applications. Explore how the strongest 3D printing materials are shaping industries like aerospace, medicine, and automotive manufacturing.

Aerospace Industry

In aerospace, where weight and strength are paramount, 3D printing with advanced materials has revolutionized component manufacturing.

Medical Field

The medical field benefits from biocompatible materials with the strength to withstand the demands of implants and prosthetics.

Automotive Sector

In the automotive sector, 3D printing is contributing to the production of lightweight yet robust components, enhancing fuel efficiency and overall performance.

Pushing the Limits

As we push the limits of 3D printing materials, we encounter technological barriers and witness the relentless pursuit of overcoming challenges. What’s limiting us today may pave the way for future innovations.

User-Friendly Materials

Access to the strongest 3D printing materials shouldn’t be restricted to experts. We explore the accessibility, affordability, and sustainability of these materials, making 3D printing a viable option for all.

Accessibility and Affordability

Ensuring that strong materials are accessible and affordable democratizes 3D printing, fostering innovation across diverse communities.

Ease of Printing

User-friendly materials simplify the printing process, making it feasible for enthusiasts and professionals alike to create robust prototypes and end-use products.

Sustainability

As the world embraces eco-conscious practices, the sustainability of 3D printing materials becomes crucial. Can we create strength without compromising the environment?

Comparing Strength Metrics

Understanding strength goes beyond a one-size-fits-all approach. We delve into specific metrics like tensile strength, impact resistance, and flexural strength to compare materials effectively.

Tensile Strength

The ability of a material to withstand pulling forces is critical in applications where tension is a primary concern.

Impact Resistance

For applications prone to impact, such as consumer goods and protective gear, the material’s ability to absorb and disperse energy is paramount.

Flexural Strength

In scenarios requiring bending or flexing, materials with high flexural strength ensure longevity and reliability.

Case Studies

Success stories and challenges overcome provide invaluable insights into the real-world applications of the strongest 3D printing materials.

Success Stories

Highlighting instances where industries have embraced 3D printing for its strength and efficiency.

Challenges Overcome

Navigating the hurdles encountered in the pursuit of stronger materials and how innovation triumphed.

How to Choose the Right Material

Selecting the right material involves considering project requirements, budget constraints, and the environmental impact of the chosen material. A guide to making informed decisions in the world of strongest 3D printing materials.

Project Requirements

Tailoring material choices to meet the specific demands of a project ensures optimal performance.

Budget Considerations

Balancing strength and cost is a delicate dance; we explore how to strike the right chord.

Environmental Impact

In an era of sustainability, understanding the ecological footprint of materials is paramount. Can we build a stronger future without compromising our planet?

Striking the Balance

In the pursuit of strength, we often encounter dilemmas. Explore the delicate balance between strength vs. flexibility, weight vs. durability, and customization vs. standardization.

Strength vs. Flexibility

Choosing materials that offer the perfect blend of strength and flexibility for varied applications.

Weight vs. Durability

In industries where weight matters, finding materials that are both lightweight and durable is a constant challenge.

Customization vs. Standardization

Balancing the need for customized solutions with the efficiency of standardized materials in 3D printing.

Industry Insights

Expert opinions and market trends shed light on the present state and future direction of strongest 3D printing materials.

Expert Opinions

Insights from industry experts on the current landscape and the future trajectory of 3D printing materials.

Market Trends

Identifying the trends that are shaping the industry and influencing material development.

Emerging Technologies

A glimpse into the future, exploring the technologies on the horizon that promise to redefine the concept of strength in 3D printing.

Testing and Quality Assurance

Ensuring the strength of 3D printing materials involves standardized tests, industry certifications, and a commitment to continuous improvement.

Standardized Tests

The rigorous testing procedures that materials undergo to ascertain their strength and reliability.

Industry Certifications

Recognizing the certifications that vouch for the quality and strength of 3D printing materials.

Continuous Improvement

How the industry is committed to continually improving material strength, pushing the boundaries further.

FAQs

How to Improve Print Strength?

Discover practical tips to enhance the strength of your 3D prints, from optimizing settings to choosing the right materials.

Are Strong Materials Always Heavy?

Demystifying the misconception that strength equates to heaviness, exploring materials that defy this stereotype.

Can 3D Printing Replace Traditional Manufacturing?

Unraveling the role of 3D-printing in manufacturing and whether it poses a real challenge to traditional methods.

Is Metal Stronger Than Polymer?

Comparing the strengths of metal and polymer materials, exploring their respective advantages and limitations.

Challenges in 3D-Printing Strength?

Acknowledging the hurdles in achieving optimal strength in 3D-printing and how the industry is addressing these challenges.

What’s Next for 3D-Printing Materials?

A glimpse into the future of 3D-printing materials, exploring potential breakthroughs and innovations.

Conclusion

In the ever-evolving landscape of 3D-printing, the quest for the strongest 3D printing material is an ongoing adventure. As technology advances and industries embrace the possibilities, the future holds exciting promises of stronger, more resilient materials.

Black & White 2-Pack

- PLA Filament 1.75mm Bundle 2kg for 3D Printing

- Ender PLA Filament No-Tangling

- Strong Bonding & Overhang Performance

- Accuracy +/- 0.02mm

You may also like how to use the OpenAI Chat GPTs new feature